Custom

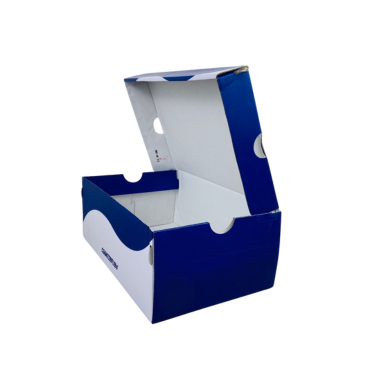

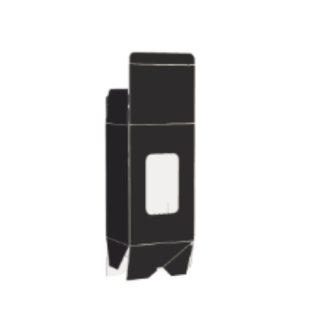

Corrugated Mailer Box

Designed for Delivery,

Built for Branding.

- Durable Corrugated Construction

- Easy to Assemble & Seal

- Ships & Storage Flat

- Premium Printable Surface

- Efficient Storage & Handling

- Highly Recyclable & Biodegradable

The Complete Shipping Solution:

Protect Your Products, Promote Your Brand

Key Features of Our Mailer Boxes:

-

Unmatched Convenience & Efficiency

-

Self-Locking Base: Features an auto-bottom design that locks securely without the need for tape, enabling rapid assembly and reducing labor costs.

-

Ships Flat: Stores and ships flat, dramatically saving on warehouse and freight space.

-

Ready to Ship: Easily filled, closed with a tuck-top or flip-top lid, and labeled—streamlining your entire fulfillment process.

-

-

Superior Product Protection

-

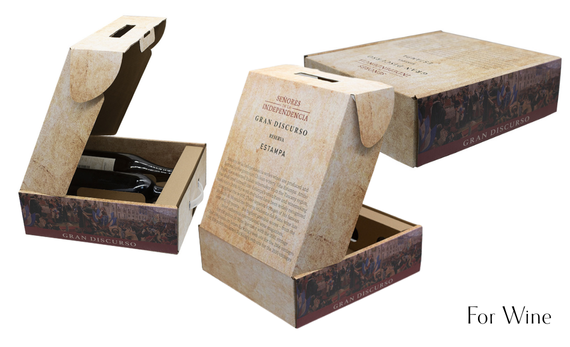

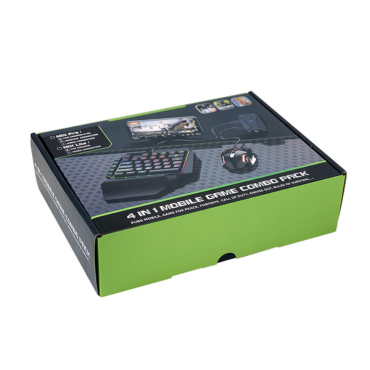

Durable Corrugated Construction: Made from sturdy, crush-resistant corrugated cardboard (like E-flute or B-flute) that provides excellent protection during transit.

-

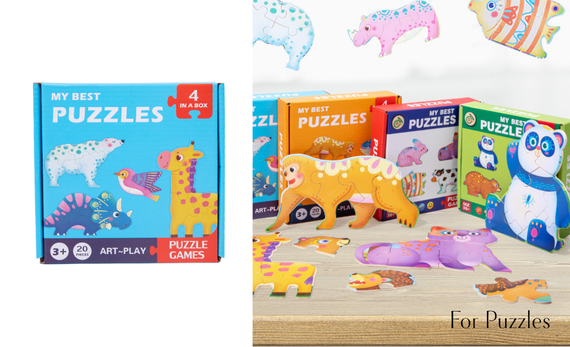

Secure Fit: Available in standard and custom sizes to ensure a snug fit for your product, minimizing movement and damage.

-

High Stacking Strength: Designed to withstand being stacked in delivery trucks and warehouses, ensuring your product arrives in perfect condition.

-

-

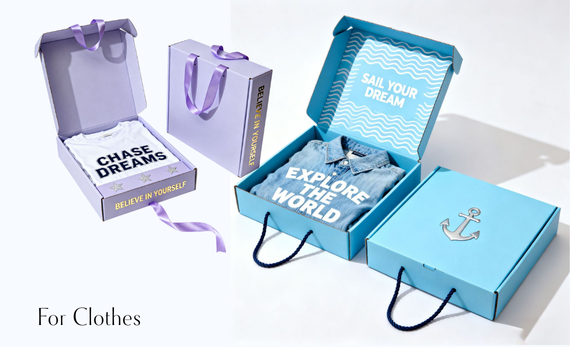

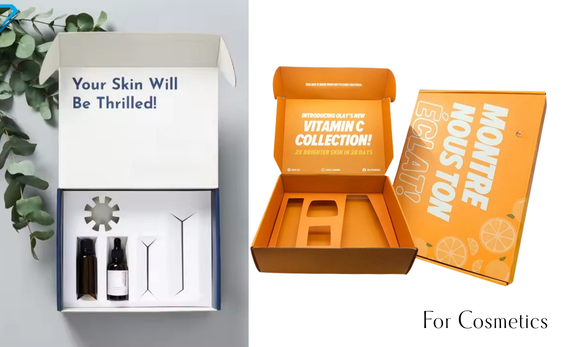

Powerful Branding & Marketing Canvas

-

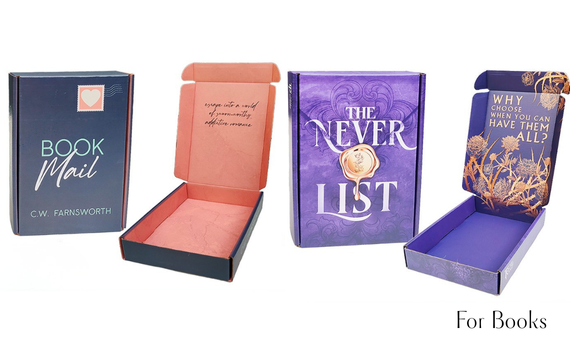

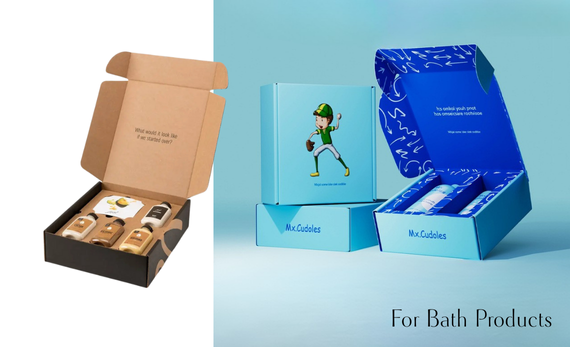

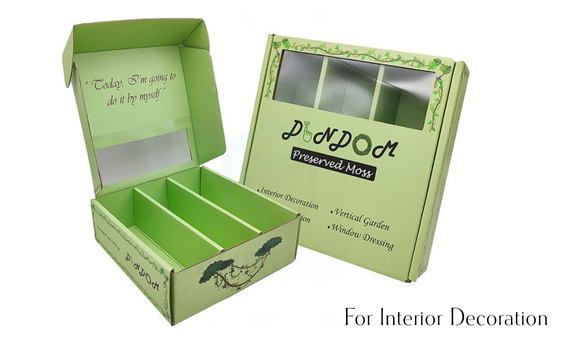

Premium Printable Surface: Offers a superior canvas for high-quality, full-color printing. Showcase your logo, brand colors, and design to make a lasting first impression.

-

Walking Billboard: Your brand travels visibly from warehouse to doorstep, generating impressions at every stage of the journey.

-

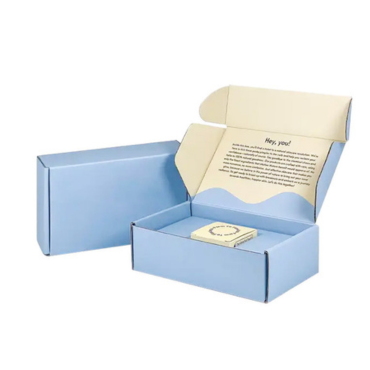

Enhanced Unboxing Experience: Transforms a simple delivery into a branded event, increasing customer satisfaction, loyalty, and social media sharing.

-

-

Sustainable & Professional Choice

-

Eco-Friendly Material: Typically made from recyclable and biodegradable materials, with options for high post-consumer recycled content.

-

Reduced Waste: Eliminates the need for excess outer packaging or additional tape.

-

Professional Appearance: Presents a polished, cohesive, and trustworthy image that reflects the quality of your brand and product.

-

Ready to get a quote or need more info? Contact our team.

Finding the Perfect Fit: A Mailer Box Style Guide

Elevated Unboxing: Cosmetic Mailer Box Design Inspirations

Damage-Free & Sustainable: Custom Self-Sealing Boxes for Skincare Brands

All-in-one Solution for printing and packaging

Control and customize the size to personalize and beautify your product.

Massive selection of materials. Certainly can have one to suit your printing and packaging.

Choose the ideal printing method for your item to make your brand shine.

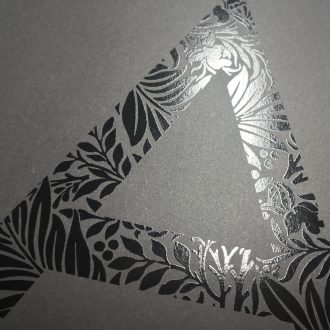

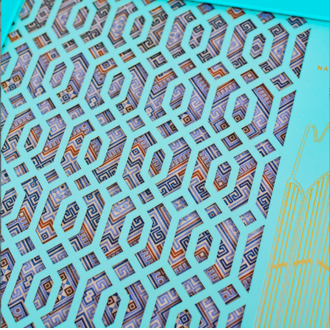

A unique finish for printing items and packaging always wins customer attention.

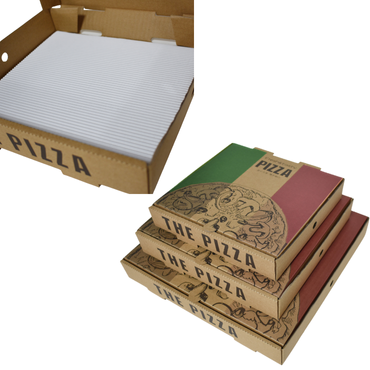

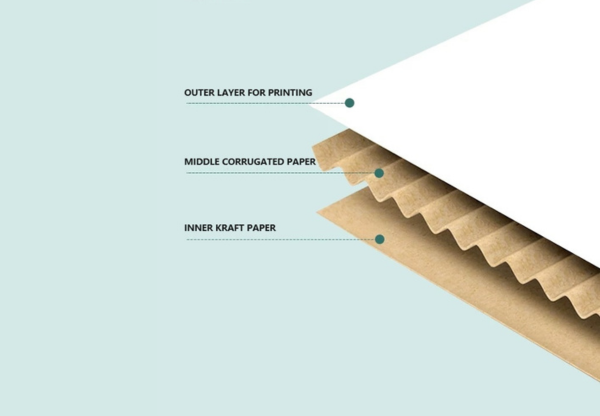

Structural of corrugated cardboard boxes

The corrugated cardboard boxes are mainly composed of three kinds of materials: corrugated paper, surface paper, and glue.

Among them, corrugated paper is the most important material for corrugated cardboard boxes. It is composed of layers of uneven corrugated cardboard, which can effectively resist external pressure and collision.

Face paper is a smooth paper covering the outside of corrugated paper, which can provide good printability and aesthetics for corrugated boxes.

Glue is used to fix the face paper and corrugated paper together.

Corrugated boxes with printing

The thickness of the inner flute can be modified to create different degrees of strength in the corrugated cardboard. There are 5 standard thicknesses in the US, indicated by letters A through F. The letter indicates when it was invented, and not the relative size.

Shipping cartons with printing

Within corrugated cardboard, there are different types of construction depending on the end product requirements. Meipak can create single wall, double wall, specific flute sizes, burst strength, edge crush strength and more. Special surface treatments, coatings and coverings can be provided as well.

Zipper corrugated mailer box

Based on the structure of traditional corrugated cardboard boxes, a zipper design has been added. It can serve both protective and advertising purposes, as well as confidentiality and a one-time simple opening.

Printing and Packaging Inspiration

- Surface Finish

- Packaging Box Styles

- Paperboard

Frequently asked questions

The usual finish time is between 15 days. However, it may vary depending on:

- Material

- Order Quantities

- Shipping routes

MOQ: 500 units for printing corrugated cartons,

1000 units for small corrugated boxes.

Contact us for exact MOQs tailored to your project.

Printing options include:

- Digital printing

- Offset printing

For sampling, we recommend digital printing, which is cost-eddective.

For bulk orders, we recommend offset printing because:

- Quality – offset printing offers exceptional color fidelity that is easier to maintain

- Cost-effective – the more you print, the lower the price per unit

- Lead time – offset printing can print large quantities at a faster rate

Digital printing is also an option and provides cost-effective results for smaller orders.