Application Fields of

Corrugated Boxes & Cartons

Customize your amazing packaging with our rich experience and perfect printing. Corrugated boxes and cartons are widely used in many fields.

- Electronic products

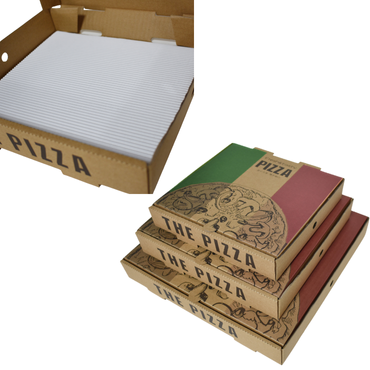

- Food industry

- Daily necessities

- Furniture field

- Pharmaceutical packaging

- Industrial and logistics packaging

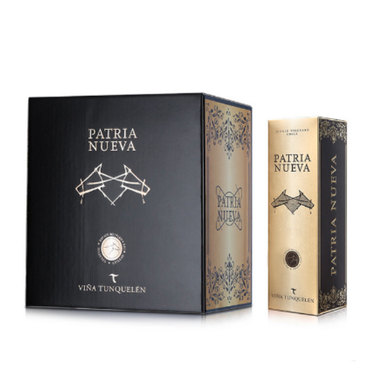

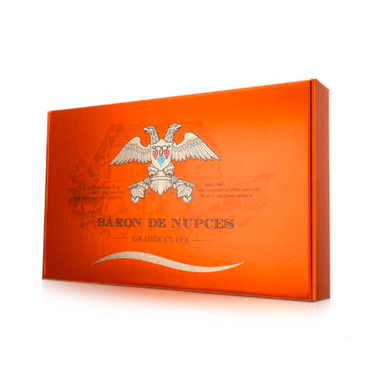

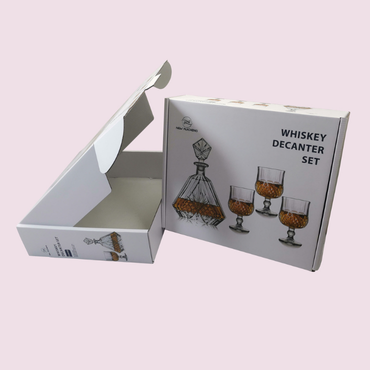

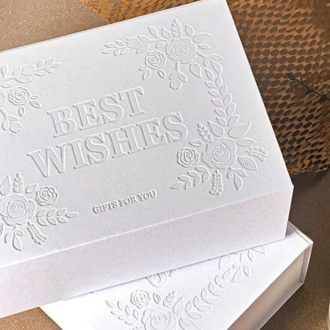

Custom Corrugated Product Packaging Boxes

Corrugated cardboard boxes have advantages such as lightweight, breathability, moisture resistance, freshness preservation, insect resistance, shock resistance, and pressure resistance,

Corrugated cardboard boxes can ensure that products are not compressed or impacted during transportation, thereby protecting the integrity of the products. The printed corrugated boxes and cartons also can effectively improve the quality of products and brand image.

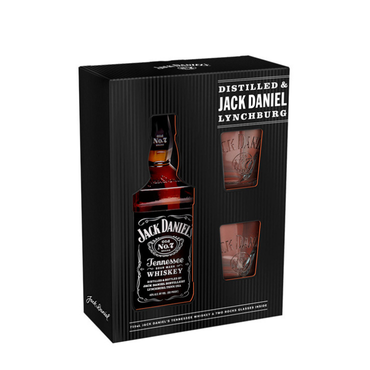

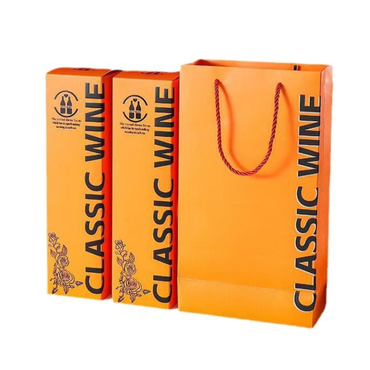

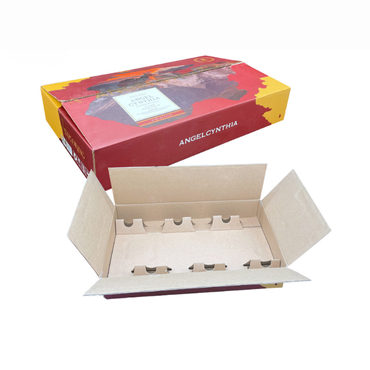

Wine corrugated packaging cartons

Corrugated packaging boxes and cartons can be used as wine gift boxes, wine holder baskets, wine delivery cartons, etc.

They are foldable, lightweight, breathable, and sturdy. They can protect these products and daily necessities from damage and play a good role in transportation and storage.

All-in-one Solution for printing and packaging

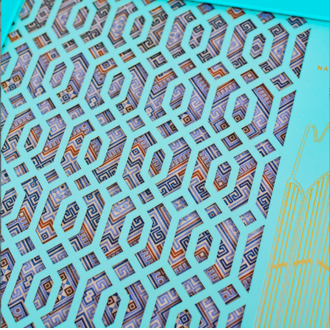

Control and customize the size to personalize and beautify your product.

Massive selection of materials. Certainly can have one to suit your printing and packaging.

Choose the ideal printing method for your item to make your brand shine.

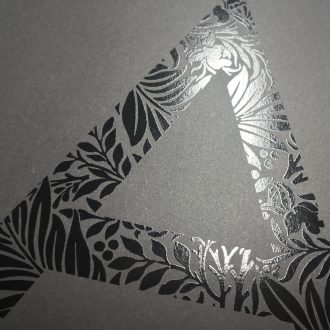

A unique finish for printing items and packaging always wins customer attention.

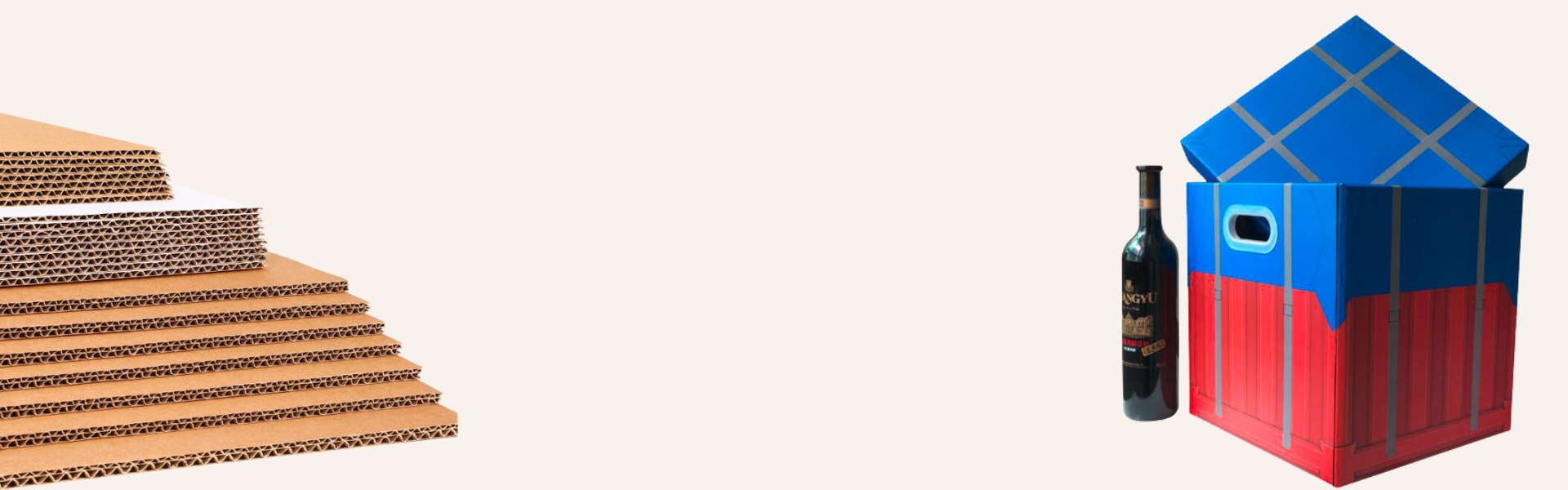

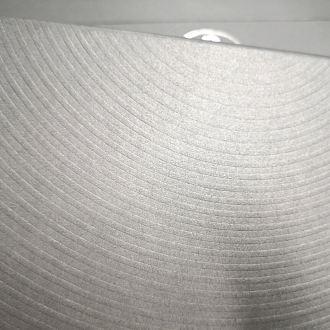

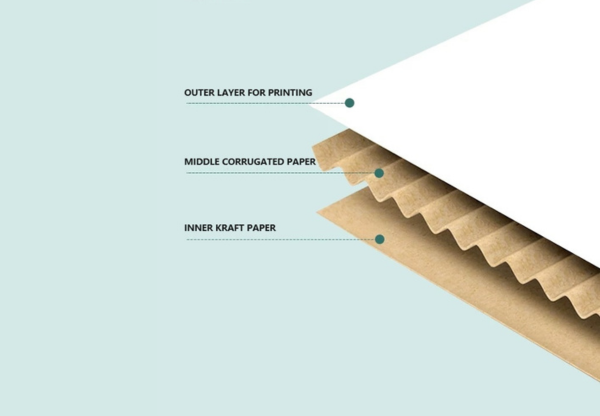

Structural of corrugated cardboard boxes

The corrugated cardboard boxes are mainly composed of three kinds of materials: corrugated paper, surface paper, and glue.

Among them, corrugated paper is the most important material for corrugated cardboard boxes. It is composed of layers of uneven corrugated cardboard, which can effectively resist external pressure and collision.

Face paper is a smooth paper covering the outside of corrugated paper, which can provide good printability and aesthetics for corrugated boxes.

Glue is used to fix the face paper and corrugated paper together.

Corrugated boxes with printing

The thickness of the inner flute can be modified to create different degrees of strength in the corrugated cardboard. There are 5 standard thicknesses in the US, indicated by letters A through F. The letter indicates when it was invented, and not the relative size.

Shipping cartons with printing

Within corrugated cardboard, there are different types of construction depending on the end product requirements. Meipak can create single wall, double wall, specific flute sizes, burst strength, edge crush strength and more. Special surface treatments, coatings and coverings can be provided as well.

Zipper corrugated mailer box

Based on the structure of traditional corrugated cardboard boxes, a zipper design has been added. It can serve both protective and advertising purposes, as well as confidentiality and a one-time simple opening.

Printing and Packaging Inspiration

- Surface Finish

- Packaging Box Styles

- Paperboard

Frequently asked questions

The usual finish time is between 15 days. However, it may vary depending on:

- Material

- Order Quantities

- Shipping routes

MOQ: 500 units for printing corrugated cartons,

1000 units for small corrugated boxes.

Contact us for exact MOQs tailored to your project.

Printing options include:

- Digital printing

- Offset printing

For sampling, we recommend digital printing, which is cost-eddective.

For bulk orders, we recommend offset printing because:

- Quality – offset printing offers exceptional color fidelity that is easier to maintain

- Cost-effective – the more you print, the lower the price per unit

- Lead time – offset printing can print large quantities at a faster rate

Digital printing is also an option and provides cost-effective results for smaller orders.